Plastics are good. Waste is bad.

The best way forward is to support the development of an efficient circular economy, in which our natural resources never become waste. In this context, we must find new ways to eliminate waste and maximise the use of natural capital and, at the same time, create sustainable development.

Since Valgroup’s inception in the 1970s, sustainability has always been part of the company’s DNA, and is fully integrated into its strategy to support the development of a robust circular economy for plastics. Valgroup is set to shape the future of sustainable packaging.

The ongoing packaging revolution has been driven by the following megatrends:

• A global affluent middle class

• Technology

• Sustainability

• Shifting demographics and social change

• Rapid urbanisation

• Climate change and resource scarcity

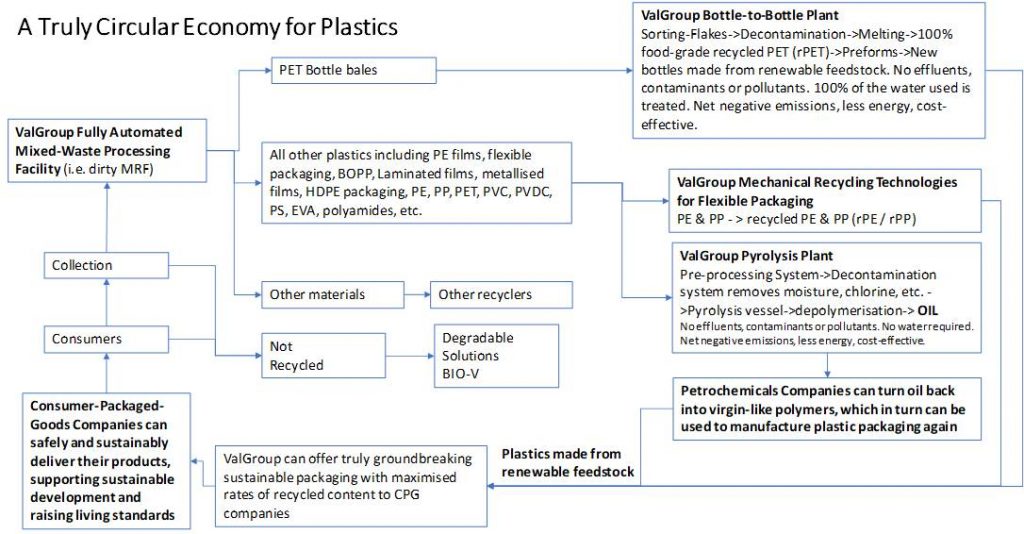

Sustainability is an unstoppable force which will transform businesses across the globe. In particular, the rational use of natural resources is imperative. Valgroup aims to build a truly circular economy, in which plastics never become waste. To that end, it has developed a number of groundbreaking sustainable technologies, processes and solutions as follows:

Valgroup Sustainable Innovation

Annually, Valgroup recycles over 135,000 tonnes of plastics, preventing this material from ending up in landfills and, subsequently, the wider environment. Valgroup aims to eliminate plastic waste and pollution at source. This can be achieved by setting up large-scale recycling plants and investing in disruptive technologies such as:

Mechanical Recycling (Re-V Cycle products): Valgroup has led the way in the plastics recycling sector. Altogether, its PET Recycling plants in Brazil, Mexico and Spain recycle over 300 million plastic bottles per month.

Pyrolysis Plants (Re-V Cycle products): This disruptive technology uses pyrolysis to turn all types of plastics into oil, which in turn can be used to produce virgin-like plastics, in a truly circular fashion.

A Fully Automated Mixed-Waste Processing Facility (dirty MRF): In order to increase access to plastic waste on a large-scale basis, Valgroup has invested in a groundbreaking mixed-waste processing facility, which employs state-of-the-art equipment to sort all types of materials at landfill sites.

Packaging Design Optimisation (Super-R): Valgroup’s Super-Recyclable (Super-R) packaging is fully recyclable and includes laminated packaging, flow packs, stand-up pouches, bar soaps, squeeze tubes and so on. Nanotechnology also provides enhanced barrier properties to extend storage life, reducing food and product waste significantly.

Load Test Centre: Valgroup has two world-class research centres located in Lorena in Brazil and Findlay, Ohio in the US, which are able to optimise the use of plastics.

VALTRAC: The VALTRACTM system is a total solution, including hardware and software, that monitors plastics use in real time.

Renewable Resources (V-Green products): Valgroup is certified by leading organisations to manufacture packaging using bioplastics.

Enhanced Biodegradation (Bio-V products): Valgroup’s product portfolio also includes solutions with enhanced biodegradability.

A Solvent Recycling Plant: The Valgroup Solvent Recycling Plant (VSRP), which is able to recycle virtually all solvent that is used at Valgroup’s plant in Lorena.

Renewable Energy: A significant percentage of Valgroup’s energy comes from renewable sources.

Plastics play a vital role in our society. From aircrafts and vehicles to medical and electronic devices and packaging, plastics have improved safety, sanitation and living standards thanks to their optimal mechanical properties – they are resistant, low in weight, malleable and cost-effective. Moreover, they are significantly less energy and water intensive than the alternatives, and also have a very low carbon footprint, making plastics one of the most useful and sustainable materials ever invented. Plastics are indispensable if we want to build a better future for this and future generations.

Written by Cesar Sanches, PhD, MSc (Econ), Director of Strategic Marketing and Sustainability, Valgroup. Find out more about the Valgroup Sustainable Innovation here.